Engineering Excellence Meets Energy Efficiency

Proprietary heat exchanger technology designed for industrial reliability with precision engineering. Proven technology that delivers 30% energy savings.

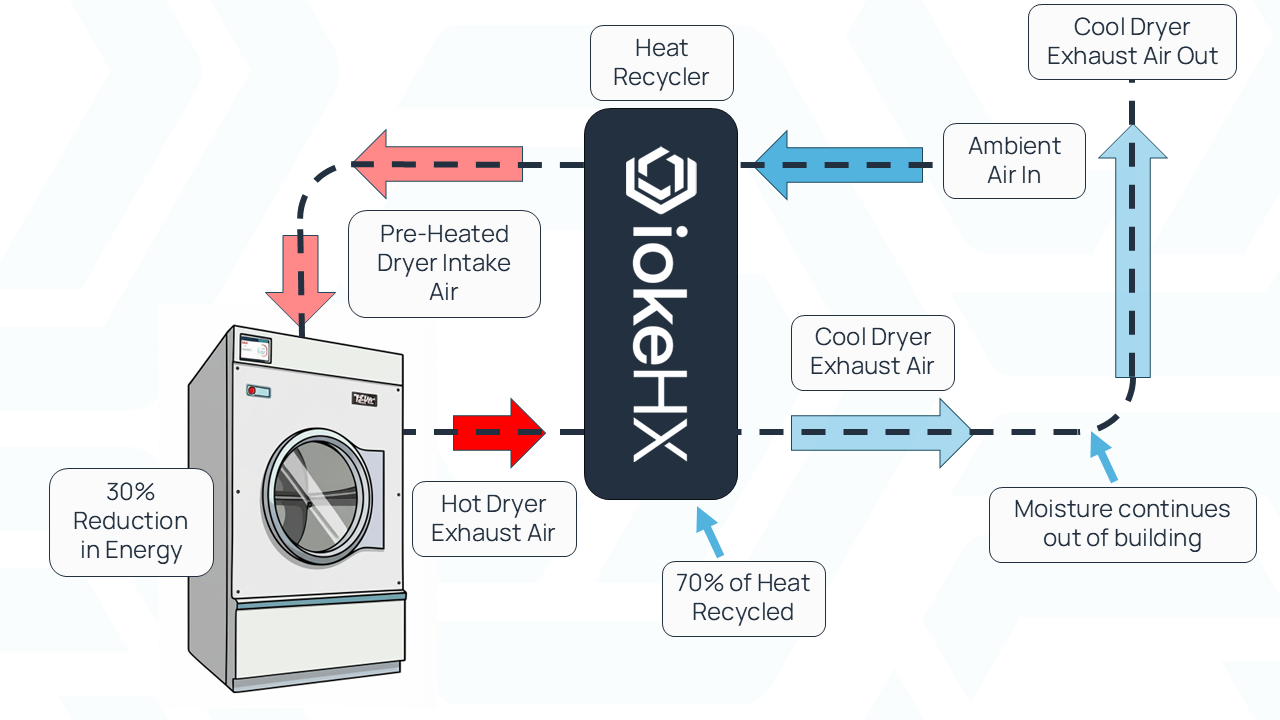

How IokeHX Energy Recovery Works

Our three-step energy recovery process captures waste heat and converts it into measurable energy savings.

Heat Capture

Our proprietary heat exchanger design achieves 70% heat transfer efficiency from dryer exhaust air. Our proprietary design maximizes surface area for optimal heat transfer efficiency.

- ✓ 70% heat transfer efficiency

- ✓ Continuous operation

- ✓ Self-cleaning technology

Heat Transfer

Captured heat is efficiently transferred to incoming fresh air through our advanced heat exchange matrix. Field-tested reliability ensures optimal performance.

- ✓ Advanced heat exchange matrix

- ✓ Minimal pressure drop

- ✓ Consistent performance

Energy Savings

Preheated air reduces energy demand by up to 30%, delivering operational cost savings. Expected payback: 2-3 years with improved drying efficiency through preheated air.

- ✓ 30% average energy savings

- ✓ Improved drying efficiency

- ✓ Expected payback: 2-3 years

Retrofit-Ready Design

Seamlessly integrate with existing dryer systems without major modifications or extended downtime.

Easy Integration

Our energy recovery systems are designed for simple integration with existing industrial dryer installations. No major infrastructure changes required.

- ✓ Compatible with most dryer brands

- ✓ Minimal ductwork modifications

- ✓ Standard electrical connections

- ✓ Professional installation team

Minimal Downtime

Installation typically completed in 1-2 days with minimal operational disruption. Our experienced team ensures smooth deployment.

- ✓ 1-2 day installation window

- ✓ Scheduled during maintenance periods

- ✓ Comprehensive training included

- ✓ 24/7 technical support

Custom Engineering Assessment

Each system is custom-built for your specific facility. Our engineering team provides detailed assessment and sizing recommendations.

Request Engineering Assessment

Self-Cleaning Technology

Advanced self-cleaning heat exchange technology reduces maintenance requirements and ensures consistent performance over years of operation.

Low Maintenance Benefits:

- ✓ Automatic debris removal during operation

- ✓ Extends equipment life significantly

- ✓ Minimal manual cleaning required

- ✓ Consistent heat transfer efficiency

- ✓ Industrial-grade components

American Engineering Heritage:

Built with precision manufacturing standards of American industrial excellence. Every component is designed for long-term industrial performance.

Performance Data & ROI

Real-world performance data demonstrates consistent energy savings and fast return on investment.

Years Expected Payback

Expected payback: 2-3 years for most installations, with performance varying by facility size and operating conditions.

Annual Savings

Average annual energy cost savings for medium-sized commercial laundry operations (varies by facility size and usage).

Uptime Reliability

System reliability rating with minimal maintenance requirements thanks to self-cleaning technology and advanced engineering components.

Ready to see how much your facility can save?